E-mail:

exexportmachinery@126.com

Tel:

+86-15256547590

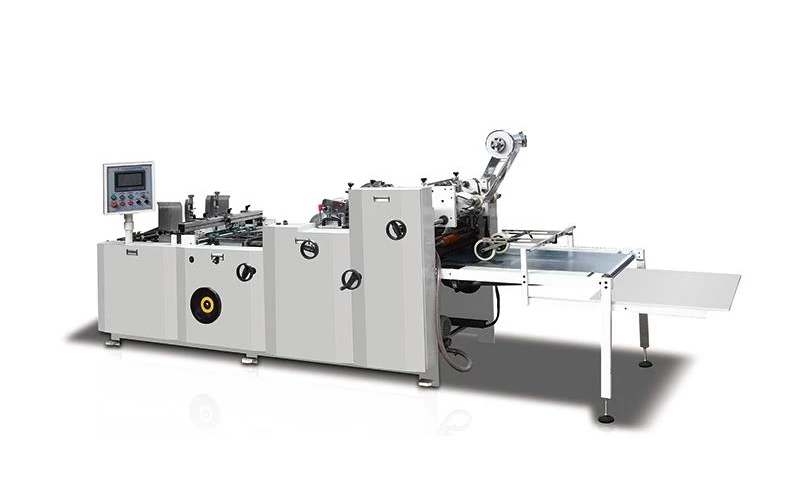

In today’s competitive market, the first impression often makes the difference between a product languishing on the shelf and a best-seller status. Transparent window patches on paper boxes, envelopes, and other packaging are a tried-and-true method to offer that critical glimpse of the product inside, captivating consumers and driving sales. This is where a window pasting machine comes into play. From paper boxes to envelopes, these window patching machines automate and elevate the window patching process to new heights. In this blog, we’ll delve into three top-of-the-line models: the TC-650 Fully Automatic Paper Box Window Film Patching Machine, the TC-1080 Automatic Window Patching Machine, and the TM-390 Full Automatic Envelope Window Patching Machine.

As the name suggests, the TC-650 Fully Automatic Paper Box Window Film Patching Machine is designed for fully automated operations, ensuring both efficiency and high-quality output. Ideal for businesses looking to scale up their packaging capabilities, this window patching machine delivers precise window film patching with minimal human intervention.

- High-Speed Production: Capable of running at high speeds while maintaining accuracy, making it perfect for large-scale operations.

- Precision: Its cutting-edge technology ensures each patch is perfectly aligned, ensuring that your product looks polished and professional.

- User-Friendly Interface: Simplifies the operation process, making it manageable even for operators with minimal technical background.

For companies that produce a variety of paper boxes, especially in industries such as cosmetics, food, and electronics, the TC-650 can be a game-changer, reducing labor costs and increasing output quality and quantity.

Moving on to another stellar option, the Automatic Window Patching Machine TC-1080 is known for its versatility and advanced features tailored for precision-driven tasks. This window pasting machine is ideal for businesses that require flexibility along with high performance.

- Versatility: Suitable for a diverse range of materials including paperboard and corrugated boards.

- High Precision: Features advanced servo control systems to ensure each window patch is applied with impeccable accuracy.

- Automated Adjustments: Allows for quick changeovers between different job types and sizes, making it a versatile asset for dynamic production environments.

The TC-1080 stands out when it comes to adaptability, accommodating various packaging materials and formats. Whether you need to patch windows in small, elegant boxes or large, sturdy cartons, EX.Export window patching machine factory has you covered.

Envelopes continue to be an essential medium for communication and marketing. The TM-390 Full Automatic Envelope Window Patching Machine is perfect for companies that aim to add a touch of transparency and appeal to their mailed messages and parcels.

- Dedicated Envelope Design: Specifically engineered to handle envelopes, ensuring flawless patches every time.

- High Throughput: Capable of processing high volumes with exceptional speed.

- Minimal Downtime: Designed for ease of maintenance, ensuring that production runs smoothly without frequent interruptions.

The TM-390 excels in delivering consistent quality and speed, crucial for businesses relying heavily on direct mail and promotional campaigns. By automating the window patching process for envelopes, it ensures that each piece not only adds value but also captures attention.

Investing in a Window Patching Machine can significantly elevate your packaging operations, adding both aesthetic and functional value to your products. Whether it's the TC-650 Fully Automatic Paper Box Window Film Patching Machine, the TC-1080 Automatic Window Patching Machine, or the TM-390 Full Automatic Envelope Window Patching Machine, each model brings something unique to the table, ensuring that you can find the right fit for your specific needs.

Incorporating advanced post press equipment into your production line not only sets you apart from the competition but also enhances your product’s marketability. The future of packaging is here, and it’s clearer than ever.