E-mail:

exexportmachinery@126.com

Tel:

+86-15256547590

In the ever-evolving landscape of the printing and publishing industry, the demand for high-quality, durable, and aesthetically pleasing books is on the rise. One of the key components in achieving this is the binding process. Among the various binding methods available, the use of automatic book binding machines has revolutionized the industry. In this blog, we will delve into the world of automatic book binding machines, exploring their benefits, types, and considerations when choosing the right machine for your needs.

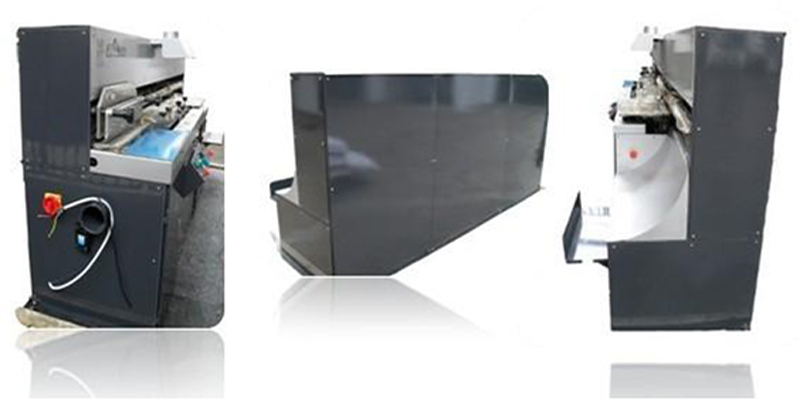

Automatic book binding machines have become a game-changer in the printing industry. These machines offer a seamless and efficient way to bind books, ensuring consistency and high quality.

Efficiency and Speed: One of the primary advantages of fully automatic book binding machines is their ability to handle large volumes of books in a short amount of time. This is particularly beneficial for commercial printers who need to meet tight deadlines. The automation reduces the need for manual intervention, allowing operators to focus on other critical tasks.

Consistency and Quality: Automatic machines ensure that each book is bound with the same level of precision and quality. This consistency is crucial for maintaining a professional appearance, especially for high-end publications. The uniformity in binding also reduces the chances of errors, ensuring that every book meets the desired standards.

Cost-Effectiveness: While the initial investment in an automatic book binding machine may be significant, the long-term savings in labor costs and increased productivity make it a worthwhile investment. The automatic book binding machine price varies depending on the features and capabilities, but the return on investment is often substantial. Over time, the machine pays for itself through reduced labor costs and increased output.

Versatility: Many modern automatic book binding machines are designed to handle various types of binding methods, making them versatile tools in a printing facility. This versatility allows businesses to cater to a wide range of customer needs, from simple booklets to complex hardcover books.

User-Friendly Operation: Today’s automatic book binding machines come with intuitive interfaces and user-friendly controls, making them accessible even to operators with minimal training. This ease of use reduces the learning curve and ensures that the machine can be operated efficiently from day one.

There are several types of automatic book binding machines available, each catering to different binding needs. Here are some of the most popular ones:

Perfect Binding Machines: Perfect binding is a widely used method for binding paperback books. It involves gluing the pages and cover together at the spine. The Digibinder automatic perfect binder is a popular choice for this type of binding. It offers a professional finish and is ideal for books with higher page counts. Perfect binding machines are known for their ability to produce books with a clean, square spine, which can be printed on for added branding.

Saddle Stitch Binding Machines: Saddle stitching involves folding sheets of paper in half and stapling them along the fold. This method is cost-effective and ideal for booklets, brochures, and magazines with lower page counts. Saddle stitch book binding machines are often used for publications that need to be produced quickly and economically, such as event programs and catalogs.

Case Binding Machines: Case binding, also known as hardcover binding, involves encasing the book’s pages within a rigid cover. This method provides superior durability and a high-end appearance, making it suitable for textbooks, coffee table books, and other long-lasting publications. Case binding machines are designed to handle the complex process of attaching the book block to the hard cover, ensuring a sturdy and professional finish.

Spiral and Wire-O Binding Machines: These machines use a continuous wire or plastic spiral coil inserted through holes along the edge of the pages, allowing documents to lay flat and enabling easy page turning. Spiral and Wire-O binding are excellent choices for presentation documents, handbooks, calendars, journals, training manuals, and cookbooks. These binding methods are particularly useful for documents that need to be opened flat for easy reference.

When selecting an automatic book binding machine, several factors need to be considered to ensure you make the right choice for your specific needs.

Budget: The automatic book binding machine price can vary significantly based on the type and features of the machine. It’s essential to determine your budget and find a machine that offers the best value for your investment. While it may be tempting to opt for a cheaper machine, it’s important to consider the long-term benefits and potential cost savings of a higher-quality machine.

Volume and Speed: Consider the volume of books you need to bind and the speed at which you need to complete the binding process. Fully automatic machines like the Sterling Digibinder for sale are designed to handle high volumes efficiently. If your business requires quick turnaround times, investing in a high-speed machine can significantly boost your productivity.

Type of Binding: Depending on the type of publications you produce, you may need a specific type of binding machine. For example, if you primarily produce paperback books, a perfect binding machine would be ideal. On the other hand, if you produce a variety of publications, you may need a versatile machine that can handle multiple binding methods. Assessing your primary binding needs will help you choose a machine that aligns with your production goals.

Durability and Maintenance: Investing in a durable machine that requires minimal maintenance is crucial for long-term productivity. Look for machines from reputable manufacturers like EX.EXPORT, known for their reliability and quality. Regular maintenance and servicing are essential to keep the machine running smoothly and to extend its lifespan.

Ease of Use: The user-friendliness of the machine is another important consideration. Machines with intuitive controls and easy setup processes can save time and reduce the likelihood of errors. Training your staff to operate the machine efficiently will also contribute to smoother production workflows.

Support and Service: Consider the level of support and service provided by the manufacturer. A reliable support system can be invaluable in case of technical issues or when you need assistance with machine setup and operation. Choosing a manufacturer with a strong reputation for customer service can provide peace of mind and ensure that you get the most out of your investment.

Automatic book binding machines are used in a wide range of applications, catering to various industries and publication types. Here are some common applications:

Commercial Printing: Commercial printers use automatic book binding machines to produce a variety of printed materials, including books, magazines, catalogs, and brochures. The ability to handle large volumes and produce high-quality bindings makes these machines essential in commercial printing operations.

Educational Publishing: Educational publishers rely on automatic book binding machines to produce textbooks, workbooks, and other educational materials. The durability and professional finish provided by these machines ensure that the books can withstand frequent use by students.

Corporate Printing: Corporations use automatic book binding machines to produce training manuals, annual reports, and other corporate documents. The professional appearance and durability of the bindings reflect positively on the company’s brand.

Self-Publishing: Self-published authors and small publishers benefit from automatic book binding machines by producing high-quality books without the need for large print runs. This allows for greater flexibility and cost savings in the publishing process.

Specialty Publications: Specialty publications, such as coffee table books, art books, and cookbooks, require high-quality bindings to enhance their visual appeal and durability. Automatic book binding machines provide the precision and quality needed for these types of publications.

The future of automatic book binding machines is promising, with advancements in technology driving innovation and improving efficiency. Here are some trends to watch for:

Automation and Integration: The integration of automation and smart technology is expected to continue, allowing for more seamless and efficient binding processes. Machines with advanced sensors and automation features will further reduce the need for manual intervention.

Eco-Friendly Solutions: As sustainability becomes a priority, manufacturers are developing eco-friendly binding solutions. This includes the use of environmentally friendly adhesives and materials, as well as energy-efficient machines.

Customization and Personalization: The demand for customized and personalized publications is on the rise. Future binding machines will offer greater flexibility in handling custom orders, allowing for unique and tailored binding solutions.

Enhanced User Interfaces: User interfaces will continue to improve, making machines even more user-friendly and accessible. Touchscreen controls, intuitive software, and remote monitoring capabilities will enhance the overall user experience.

Compact and Versatile Designs: Manufacturers are developing more compact and versatile binding machines that can fit into smaller spaces and handle a variety of binding methods. This will make it easier for small businesses and self-publishers to invest in high-quality binding equipment.

Automatic book binding machines have transformed the printing and publishing industry, offering efficiency, consistency, and high-quality results. Whether you need a perfect binding machine, a saddle stitch binding machine, or a case binding machine, there are options available to suit your specific needs. EX.EXPORT delved deep into automatic book binding machines. If you’re aiming to make your books excel at quality, durability, and a touch of class, EX.EXPORT automatic book binding machine series is your go-to option. Feel free to explore our post press machine series.

By considering factors such as budget, volume, type of binding, and durability, you can choose the right automatic book binding machine to enhance your production process and deliver exceptional results. Embrace the power of automation and take your bookbinding to the next level with the right machine. The future of bookbinding is bright, and with the right equipment, you can stay ahead of the curve and meet the evolving demands of the industry.