E-mail:

exexportmachinery@126.com

Tel:

+86-15256547590

Countless companies fall short when it comes to packaging their products and readying them for warehousing and shipping. In most cases, the fault lies more with their carton-folding and gluing equipment more so than their employees or processes. EX.EXPORT is committed to taking this issue out of the equation.

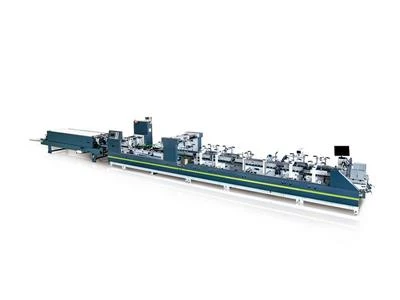

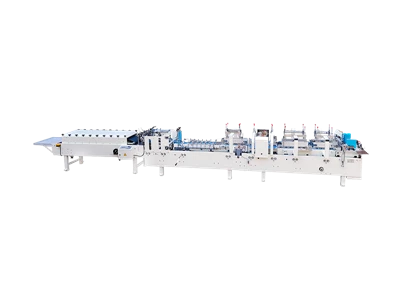

Automatic folding and gluing machines from EX.EXPORT offer a long list of features and benefits. Each one is designed to help improve speed and efficiency while taking unnecessary strain off packaging staff members.

Delays and setbacks in the packaging process can create a number of unnecessary expenses for today’s businesses, but you don't have to accept them. Feel free to explore our range of post press equipment!

1. Auto folder gluer machines must be kept clean and cleaned frequently.

2. The mechanical belt is cleaned with clean water to prevent it from slipping, especially to prevent it from sticking to the belt. The glue wheel and the glue box at the bottom of the hook must be cleaned every day after get off work, otherwise the glue inside the glue box will freeze and affect the glue effect.

3. Keep the glue box in the gluing part clean and clean, and scrub frequently.

4. Speed regulation is strictly prohibited when the governor is stopped, otherwise the belt wear will be severe.

5. The inner row of board supports, shafts, and rods must be cleaned frequently, and the use of a combination of moisturizing oil and butter can better shake it to prevent rust.

6. It is best to drive at a slow speed before turning on the machine to check whether the machine is abnormal.

Folder gluer machines have transformed the packaging industry with their revolutionary technology. These sophisticated devices have redefined the way businesses operate and offer a multitude of benefits that traditional methods simply can't match. Let's take a closer look at the advantages of EX.Export's auto folder gluer machines—investing in one of these devices could be a game-changer for your business.

1. Automatic folder gluer machines, such as our automatic pre-fold folder gluer ZH-A Series, are designed to perform complex folding and gluing tasks with pinpoint accuracy. These machines meticulously assemble each packaging unit following predefined guidelines, leaving no room for errors or inconsistencies.

2. An average industrial auto folder gluer machine is capable of processing large volumes of packaging units in a fraction of the time that manual methods require. The time you save on assembly can then be redirected to other crucial business operations, maximizing your efficiency.

3. Automated machines assemble each unit correctly the first time, minimizing overall waste. This method not only saves on material costs but makes your packaging process more environmentally friendly.

The combination of speed, precision, and waste reduction can boost your productivity by leaps and bounds! You don't have to compromise on quality to produce a higher number of packaging units. Automating your folding and gluing processes can boost your bottom line and free up your staff to focus on more strategic areas of the business.