E-mail:

exexportmachinery@126.com

Tel:

+86-15256547590

Suitable Paper: Kraft paper, art paper, white board paper, white cardboard, (including film adhesive paper and matt laminated paper) etc.

Glue: Use imported hot-melt glue. Environment friendly. The glue speed, sol temperature, layer thickness & location can be adjusted easily and independently.

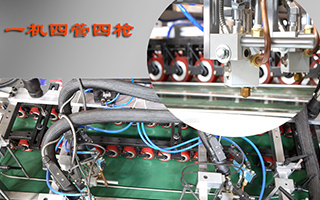

With four spray guns, each gun can independently control the spray length & thickness. Four glue guns can work at the same time.

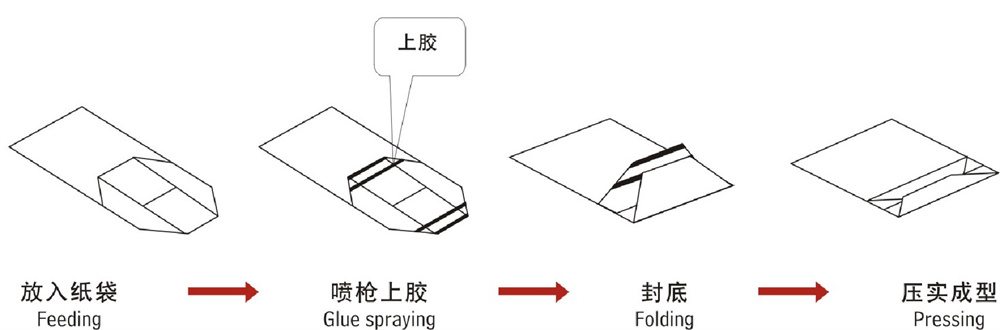

1)Working Procedure

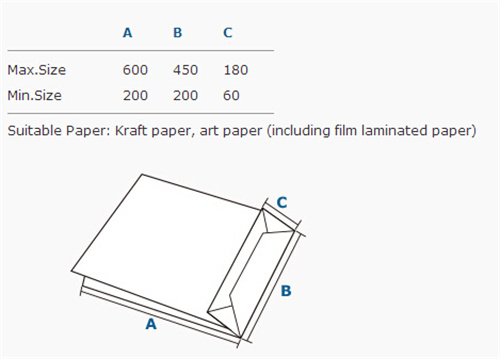

2)Range for Machining

Suitable for gluing all kinds of medium & top grade paper bag bottom.

Specification:Bag length: 135mm~560mm Bag width: 160mm~500mm.

Sheet weight: 100g~350g Bottom width:60mm~180mm

Speed: 70bags/min

3) Suitable paper

4)Machine Features

Suitable Paper: Kraft paper, art paper, white board paper, white cardboard, (including film adhesive paper and matt laminated paper) etc.

Glue: Use imported hot-melt glue. Environment friendly. The glue speed, sol temperature, layer thickness & location can be adjusted easily and independently.

With four spray guns, each gun can independently control the spray length & thickness. Four glue guns can work at the same time.

| Screw Adjusting Device | Paper Press & Collection Device |

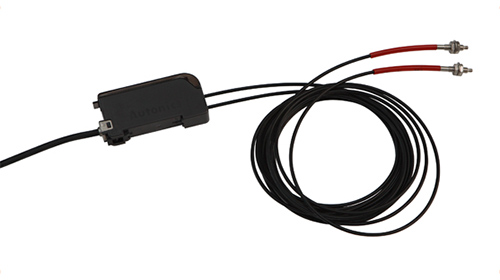

Adopt self-developed motion controller, with the fiber-optic, the glue precision can be controlled within 2-3mm.

| Optical Fiber Communication | Motion Controller |

5)Use of this machine compared with manual working (Production, Supplies, Quality)

According to 36,000 bags per day (8 hours), single machine needs 2 skillful operators.

Manually needs 7 skillful bottom-gluing workers. Each month saving labor cost: 5persons×3000RMB=15000RMB(about 2,400USD).

ZB50B makes uniform size, glue less and no excess glue, keeps bag surface clean and smooth. The biggest advantage is it can glue by point and do not affect the bag’s carrying capacity. After manually pasting, the bags need to dry 1-2 hours before packaging.

Other advantage of machine lay on speed, efficiency and bag quality.

6)Main Parts

NO. | Name | Producing place | Brand | NO. | Name | Producing place | Brand |

1 | Frequency changer | French | Schneider | 6 | Main bearing | Japan | NSK |

2 | Controller | China | Zenbo | 7 | Opxical fiber | Korea | Autonics |

3 | Operating belt | Japan | PVC | 8 | Air compressor | Shenzhen(China) | Jucai |

4 | Glue-smelting Box | USA(Taiwan) | Nordson (Yihheh) | 9 | Bearing | Japan | NSK LJK ACHI |

5 | Electrical element | French | Schneider | 10 | Touch screen | Taiwan | Delta |