E-mail:

exexportmachinery@126.com

Tel:

+86-15256547590

EX.EXPORT leads in manufacturing of paper& film jumbo roll to narrow rolls slitting rewinding machine and roll to sheets cutting machine, for printing and packaging products industry. We develop and build the machinery and the control systems that manage the machinery. We will use our rich experience to continuously improve the performance of slitting machine& sheeting cutter.

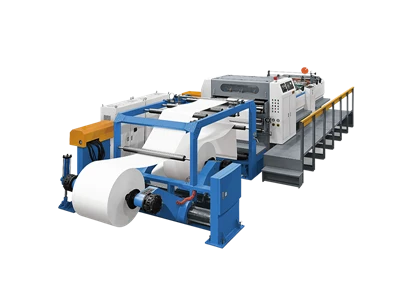

1. A slitting machine, commonly called a slitting rewinding machine, is a machine used with paper, film, and foil material to convert a wide roll of material into several thinner rolls. The slitter starts by unwinding a master or mill roll, then slits the unwound material into various widths. Finally, it completes the process by rewinding the slit material onto cores of different widths. A slitter can be designed in many configurations, depending on the customer's needs.

2. A sheeting cutter: A paper finishing operation involving the cutting of manufactured paper rolls into individual sheets, typically performed on a sheeting cutter. A sheeting cutter consists of a back-stand, where the paper roll is held, a single rotary cutter or double rotary cuter, and a layboy used for stacking and jogging cut sheets. The single rotary cutter has a stationary bed-knife contacted by another knife mounted on a rotating cylinder. The paper web is cut when the rotating knife contacts the stationary knife. A double rotary cutter replaces the stationary knife with a second rotating knife. The speed with which the rotating knife turns is adjusted relative to the speed of the paper web moving through the blades to produce the specified sheet size.