E-mail:

exexportmachinery@126.com

Tel:

+86-15256547590

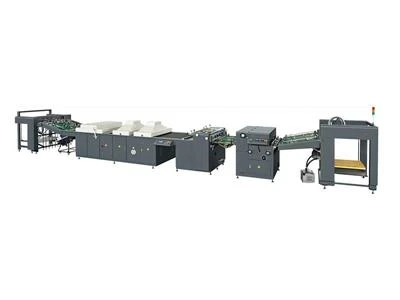

EX.EXPORT's UV coating equipment, offered by the leading UV coating machine factory in China, increases the perceived quality of the product, whilst also protecting the print. In addition, it is an economical and user-friendly varnishing machine that can be easily applied by adding spot finishes or additional processes to the entire sheet. There are also new, more Eco-friendly post press equipment options available, which is a big plus!

UV coating machine for printing uses a special varnishing process in which we cure the varnish by exposure to ultraviolet light rather than heat. UV coating varnish machine results in a more durable, protective, and slick-looking finish than standard varnishing.

As with printing varnish, UV coating varnishing machines are glossy in the resulting finish. They can also be applied to the entire surface or to specific areas to emphasize or highlight an element of the design, in which case the equipment is called "spot UV coating machine". The UV coating material is water-based and applied using special printing machines equipped with an ultraviolet drying space. As light cures the coating rather than heat, it dries faster than standard varnishes and results in a more resilient surface.

A UV coating machine, also known as a UV coater, is commonly designed to enhance the appearance and durability of printed materials. The process begins by feeding the printed sheets into the machine, where a liquid UV coating is applied evenly across the surface. This coating can be either glossy or matte, depending on the desired finish.

Once the coating is applied, the sheets pass under ultraviolet (UV) lamps. These lamps emit UV light, which instantly cures and hardens the coating. This rapid curing process not only speeds up production but also ensures a smooth, high-quality finish that is resistant to scratches, smudges, and other forms of wear and tear.

As an essential piece of post press equipment, UV coating equipment are versatile and can handle a variety of substrates, including paper, cardboard, and plastic. They are widely used in industries such as packaging, publishing, and commercial printing to add a professional touch to products like brochures, business cards, and book covers.

Investing in a UV coater can significantly elevate the quality of your printed materials, making them more appealing and durable. Contact EX.EXPORT today to learn more about our range of UV coating equipment and how it can benefit your business!

Choosing UV coating equipment from EX.EXPORT offers numerous advantages that enhance both the quality and efficiency of the printing processes. Our UV coating machine for printing significantly increases the perceived quality of printing products while providing robust protection for the print. It is an economical and user-friendly solution, capable of applying spot finishes or full-sheet coatings with ease.

Our UV varnishing machines are equipped with advanced features such as UV curing and IR drying devices, digital frequency converter speed control, and independent conveyor drives. The larger diameter coating rollers ensure a smoother and brighter finish. Safety is paramount, with full coverage splash guards, safety lockers on all doors, and protection against UV radiation.

The UV coating equipment, such as EX.EXPORT's SGZ-C-UI1040Z-A UV coating machine for printing, supports both UV and water-based varnishes, suitable for light or thick paper, and offers accurate spot coating. Integrated PLC control simplifies operation and troubleshooting, while the fully automatic process from feeding to delivery meets CE safety requirements. Additionally, eco-friendly varnish options are available, making our equipment a sustainable choice.

With its compact design, easy mobility, and high-quality components from renowned international brands, EX.EXPORT's UV coating equipment is ideal for enhancing the dimensional quality and surface protection of various printed materials.

Regular maintenance for UV coating equipment includes cleaning lenses and reflectors, checking UV lamp intensity, replacing worn bulbs, ensuring proper alignment of coating heads, lubricating moving parts, and inspecting electrical components. Monitor curing performance and maintain fluid delivery systems to prevent clogs.

To contact EX.Export, use WhatsApp:+8615256547590 or email: exexportmachinery@126.com; Visit our official website: www.exexportmachinery.com for verified contact details. Include specifics about UV Coating Machine needs in inquiries.

Payment method of EX.Export typically bank transfers (T/T), 30% deposit and 70% before delivery. It also based on order size and terms. Confirm specifics with us before place the order and discuss expedited options if needed.

Delivery time for a UV coating equipment typically ranges from 3-8 weeks, depending on our lead times, customization, and order volume. Confirm specifics with us before place the order and discuss expedited options if needed.