E-mail:

exexportmachinery@126.com

Tel:

+86-15256547590

ZSZB-D model automatic paper cup forming machine is the latest model which use the high level technical to improve,use the interval paper feeding, ultrasonic(heater)sealing, robot hand cup body transfer,oiling, bottom punching, bottom folding...

ZSZB-D model automatic paper cup forming machine is the latest model which use the high level technical to improve,use the interval paper feeding, ultrasonic(heater)sealing, robot hand cup body transfer,oilling, bottom punching, bottom folding, pre-heating, knurling, cup collection to form the cup,whole machine use the single shaft driving system, open cam system, and gear driving, automatic oil lubrication, machine use the sensor alarming system, it is an idea machine based on old model(three plates chain driving machine model).

Type: | ZSZB-D |

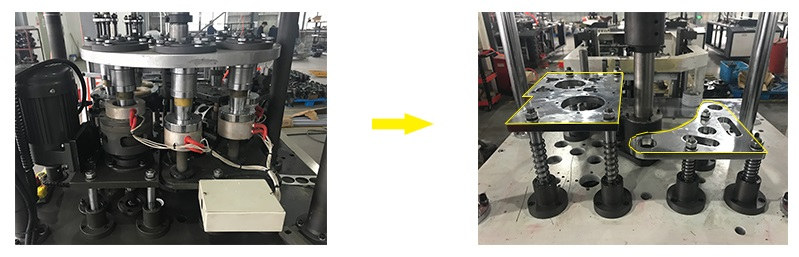

Cup size: | 3-12oz(Different size mold exchanged) |

Suitable paper material: | 150-380g/m2(single or double PE-coated paper) |

Capacity: | 70-90pcs/min |

Power source:: | 380V 50HZ(please inform us your power in advanced) |

Working power: | 4KW |

Weight: | 2000KG |

Total Power: | 8KW |

Package size: | 2800 x 1600 x 1800 mm |

Working Air Source: | Air pressure 0.4Mpa;Air out-put:0.6m3/min |

A: Top diameter: Min 50mm---Max 95mm B: Bottom diameter: Min 30mm---Max 65mm C: Total height: Min 33mm---Max 116mm D: Bottom knurling depth: Min 4mm---Max 10mm E: Rim diameter: Usually Φ2.5---Φ3 |

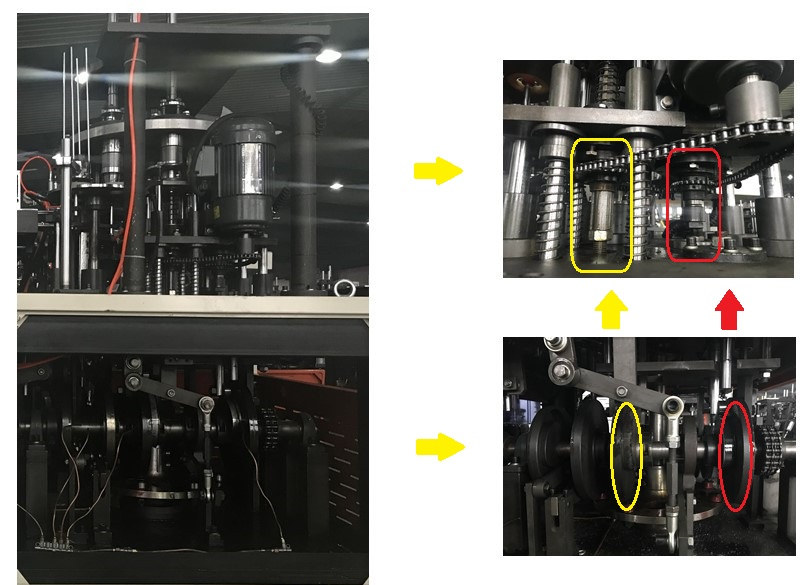

Use the vertical shaft system,open cam and gear driving system,automatic oil lubrication.

Forming section use separated cup bottom folding pre-heating section and knurling & curling section, reduce the machine loading and improve the balance of the whole section.

Use the individual came to control the curling, knurling and pre-heating working position, more accurate, and easy to operate.

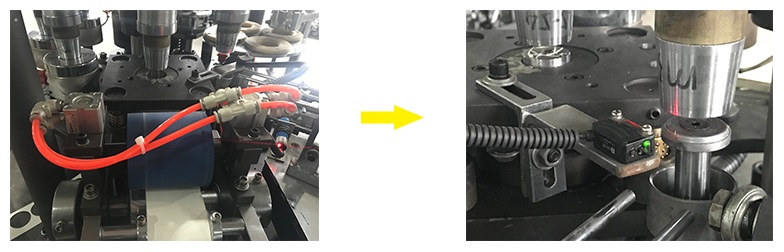

Use the Pneumatic regulating valve to the adjust bottom paper feeding instead of the bottom feeding plate, install the sensor to check bottom feeding to avoid without bottom and bottom shortage, decrease the rejection rate.

The electric parts use the famous brand.