E-mail:

exexportmachinery@126.com

Tel:

+86-15256547590

A reel-fed shopping bag-making solution refers to a production process where continuous rolls (reels) of material are fed into machinery to automatically cut, form, and assemble shopping bags. It involves a combination of design, materials selection, manufacturing processes, and potential customization options. This method is highly efficient and suitable for mass production, offering cost savings and scalability.

By adopting a reel-fed shopping bag-making solution, manufacturers can achieve high production volumes with minimal waste and labor costs, making it an attractive option for those looking to scale their operations efficiently.

Here's an overview of a Reel Fed shopping bag making solution:

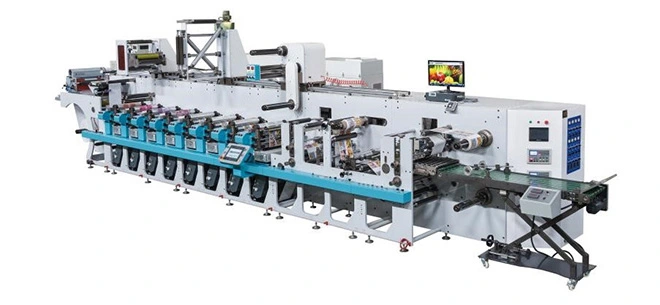

The initial step in the reel-fed shopping bag making process involves printing designs, logos, or other information onto the paper roll. Our company offers a variety of flexo printing machines for sale to meet different printing needs. These machines are designed to deliver high-quality prints with excellent color accuracy and consistency, ensuring that the final shopping bags are visually appealing and meet branding requirements.

After the paper roll has been printed, the next step is to convert it into finished paper bags. This is achieved using a roll feeding paper bag machine, which our company also offers for sale. These machines are engineered to handle the entire bag-making process efficiently, from feeding the printed paper roll to cutting, folding, and gluing it into completed bags. The result is a high-quality, durable shopping bag ready for use.